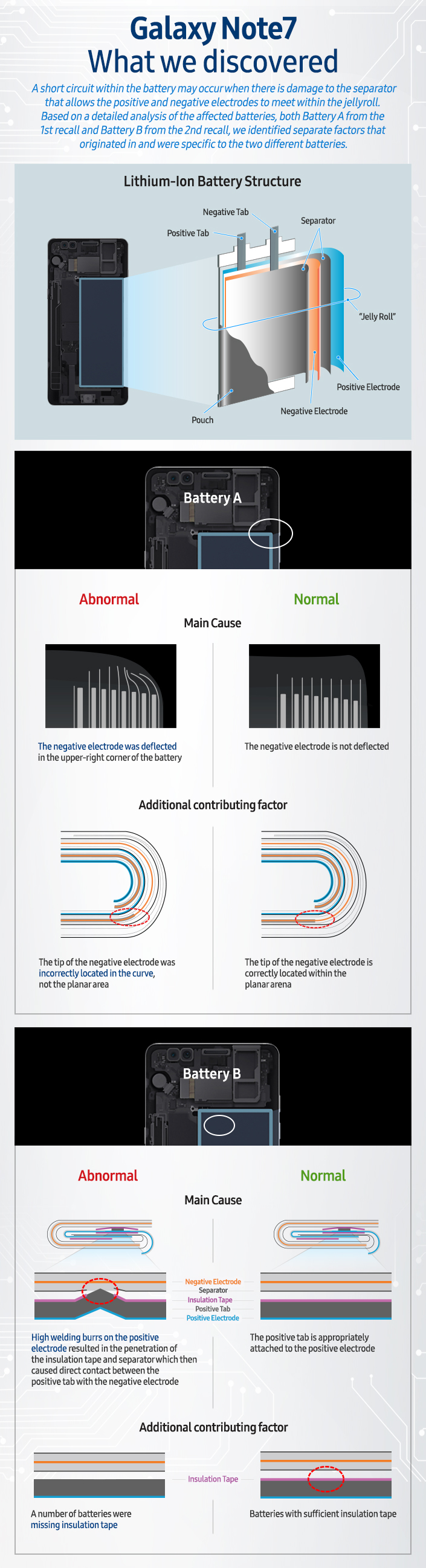

After several months of investigation, Samsung examined every aspect of the Galaxy Note7, including hardware, software and related processes over the past several months. Samsung’s investigation, as well as the investigations completed by three independent industry organisations, namely, UL, Exponent and TUV Rheinland AG concluded that the batteries were the cause of the Galaxy Note7 incidents. Samsung used two separate battery manufacturers to power the Note7 devices, however, even after changing the battery provider, the Note7 explosion saga continued.

One of the reasons Samsung provided for the failure of battery was the size, it was too large for the phone to fit in properly. Besides this, after examination from independent research companies, there may be multiple contributing factors relating to battery assembly/manufacturing and design that when combined led to the failure of the Note7 in the field. At the Battery assembly/manufacturing deformation at the upper corners of the battery were observed. Besides this, the Battery design was flawed as it had thinner separators that could lead to poorer protection and reduced tolerance to manufacturing defects. Higher energy density, in general, can exacerbate the severity of a battery failure. All these factors combined lead to Internal Short Circuit (ISC) which caused the battery to explode.

Now Samsung has developed an 8-Point Battery Safety Check to ensure safety of the battery from component to complete device. Included in the check are enhanced tests (Durability Test, Visual Inspection, X-Ray Test, Disassembling Test and OCT Test), as well as newly applied measures (Charge and Discharge Test, TVOC Test and Accelerated Usage Test). Moreover, they have also formed a Battery Advisory Group where they have invited a team of experts from academia and research centres so they can continue to provide them with their objective analysis to ensure the safety of the battery.

The causative factors are further explained in the infographic below.

Leave a Reply